Ricron MLP Panels

Dealer – EnWave Engineers India Pvt. Ltd. Ghatkesar, Hyderabad, 501301

For free consultation on suitability of the MLP panels for your application and cost estimate, please contact us through the messaging provisions given on this page.

According to the Plastic Waste Management (PWM) Rules 2016, Multi-Layer Plastic (MLP) is “any material used for packaging and having at least one layer of plastic as the main ingredient in combination with one or more layers of materials such as paper, paper board, polymeric materials, metalized layers or aluminum.

Hazards of MLP waste

Multi-layered plastics are made up of a layered composition of various types of plastics. This is a commonly used method because of the properties that the thus composed material acquires. Sometimes, the plastics material is also combined with non-plastics such as aluminium foil. Neither multi-layered plastics products made up of only plastics nor those made up in combination with a non-plastics material can be recycled.

Laminated film is used in a wide range of flexible packaging applications such as food pharma, personal care products, etc. and then disposed off.

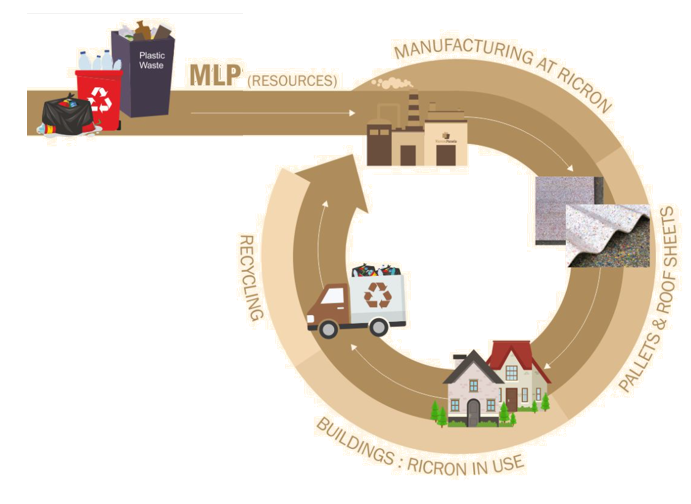

Ricron Panels recovers this non-recyclable waste and uses its propitiatory technology to convert this waste into forms of sheets that are used as a building material.

RICRON – PLAIN PANELS/SHEETS

Ricron Panel is an innovative product made from regenerated aluminum and plastic using cutting edge technology. A great cost-effective substitute for plywood and MDF in numerous industrial and commercial applications. Ricron Panels are high strength with properties such as resistance to water, termite proof, rust proof and fire resistance, thus making it an ideal weatherproof choice for various applications.

RICRON ECO-ROOF SHEETS

Ricron Eco-Roof Sheets are a great cost-effective substitute for Cement, GI Metal, Coated Roofing Sheets with applications across various domestic, industrial and commercial purposes. Ricron Eco-Roof Sheet is a certified green building product ideal for applications demanding resistance to temperature, moisture and fungus. Our sheets provide excellent durability and strength with minimal or no damage from rusting, cracking, tearing etc.

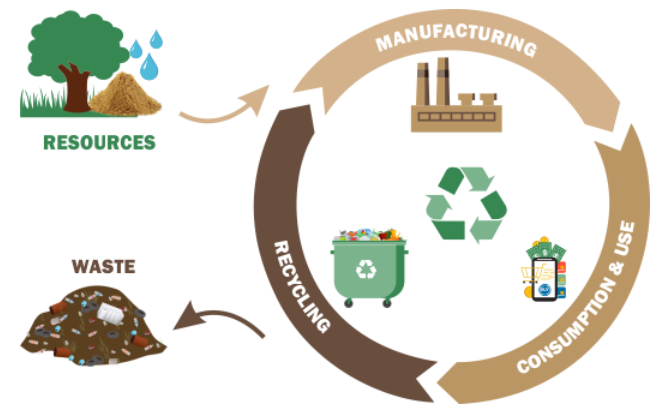

Need For Circular Economy

The world’s population is expected to peak at 10bn in 2050. Our resources, the earth’s raw materials, are not limitless. As a result, global labour and raw material costs are on the increase.

Circular economy business opportunities can offer new ways to mitigate these risks. In a circular economy, products and materials keep circulating in a high value state of use, through supply chains, for as long as possible.

Products are designed and built so that they are part of a value network where reuse and refurbishment on product, component and material level assures continuous (re-)exploitation of resources.